High Vacuum Technology

Creating an empty space is harder than it sounds. We do not mean an empty room. We mean a space with almost no air molecules. This is what we call a high vacuum technology. High vacuum technology lets us make these special spaces. It is a vital tool for many modern things.

Think about a light bulb. For it to work, the inside needs little air. If too much air is present, the filament burns out quickly. This is a simple example of why we need vacuum. But high vacuum goes much further. It helps us make computer chips, coat lenses, and study tiny particles. It even helps us understand space.

What is High Vacuum?

Vacuum is simply a space with less pressure than the air around us. We measure pressure in units like torr or pascals. Standard air pressure at sea level is about 760 torr. A rough vacuum might be a few torr. A medium vacuum could be around 0.1 torr. High vacuum starts when the pressure drops to about 10−3 torr (0.001 torr) and goes down to 10−8 torr or even lower. This is a vast decrease in the number of gas molecules in a given space.

When we create a high vacuum, we remove almost all the gas molecules. This removal changes how things behave inside the vacuum chamber. For instance, heat does not transfer well. Gases do not conduct heat effectively. In a high vacuum, there are so few gas molecules that they cannot carry much heat away. This makes high vacuum a good insulator.

Another effect is that surfaces stay clean. In air, gas molecules and water vapor stick to surfaces. In a high vacuum, these molecules leave the surface. This “outgassing” is a major challenge in vacuum technology. But once outgassed, a surface stays much cleaner. This is critical for making very small, precise devices.

How Do We Make It?

Making a high vacuum involves several steps and different types of pumps. We cannot just turn on one pump and achieve high vacuum instantly. It is a staged process. Source – smolsys.com

First, we use a roughing pump. This pump removes most of the air. It takes the pressure from atmospheric pressure down to around 10−1 or 10−2 torr. These pumps are typically mechanical pumps. They work by physically trapping and expelling gas molecules. Rotary vane pumps are common roughing pumps. They use a spinning rotor with vanes that sweep gas from the inlet to the outlet. This action compresses the gas and pushes it out.

Once the roughing pump has done its job, we switch to a high vacuum pump. These pumps work differently. They do not typically push gas out directly. Instead, they grab or trap gas molecules and remove them from the chamber.

One common type of high vacuum pump is the turbomolecular pump. Think of it as a very fast fan. It has many blades spinning at incredibly high speeds, sometimes tens of thousands of revolutions per minute. Gas molecules that enter the pump collide with these spinning blades. The blades give the molecules a momentum kick, directing them toward the pump’s outlet. This outlet is where the roughing pump removes them. Turbomolecular pumps are very effective for achieving pressures down to 10−9 torr. They are clean and do not introduce oil into the vacuum system.

Another type is the ion pump. Ion pumps use strong magnetic and electric fields. They ionize gas molecules, meaning they give them an electrical charge. These charged ions then hit titanium plates inside the pump. The titanium traps the ions. As the titanium gets coated with trapped ions, it constantly presents fresh surface to trap more. Ion pumps are excellent for achieving very low pressures, sometimes down to 10−11 torr. They are also very clean, making them ideal for ultra-high vacuum applications where even trace contaminants are a problem.

Cryopumps are another important high vacuum pump. These pumps work by cooling surfaces to extremely low temperatures, often around 10 to 20 Kelvin (about -263 to -253 degrees Celsius). At these temperatures, gas molecules freeze onto the cold surfaces. It is like the frost that forms on a very cold window. Different stages of cooling trap different types of gas. For example, water vapor freezes at a higher temperature than nitrogen or oxygen. Cryopumps are very fast at pumping and produce very clean vacuums. They do not use oil or create vibrations.

Challenges in High Vacuum

Making and maintaining a high vacuum presents several challenges. One big challenge is leaks. Even a tiny pinhole, too small to see, can let a lot of air into a high vacuum system. We need special methods to find these leaks, such as using a helium leak detector. This device sprays helium gas around the outside of the vacuum chamber. If there is a leak, the helium enters the vacuum system, and the detector senses it.

Another challenge is outgassing. As mentioned before, materials inside the vacuum chamber release gas molecules. Water vapor is a major culprit. Even metals, which seem solid, have gas trapped within their structure that can escape. To reduce outgassing, we often bake the vacuum system. This involves heating the entire chamber to a high temperature while pumping. The heat speeds up the release of trapped gases, which the pumps then remove. Once cooled, the system outgasses much less.

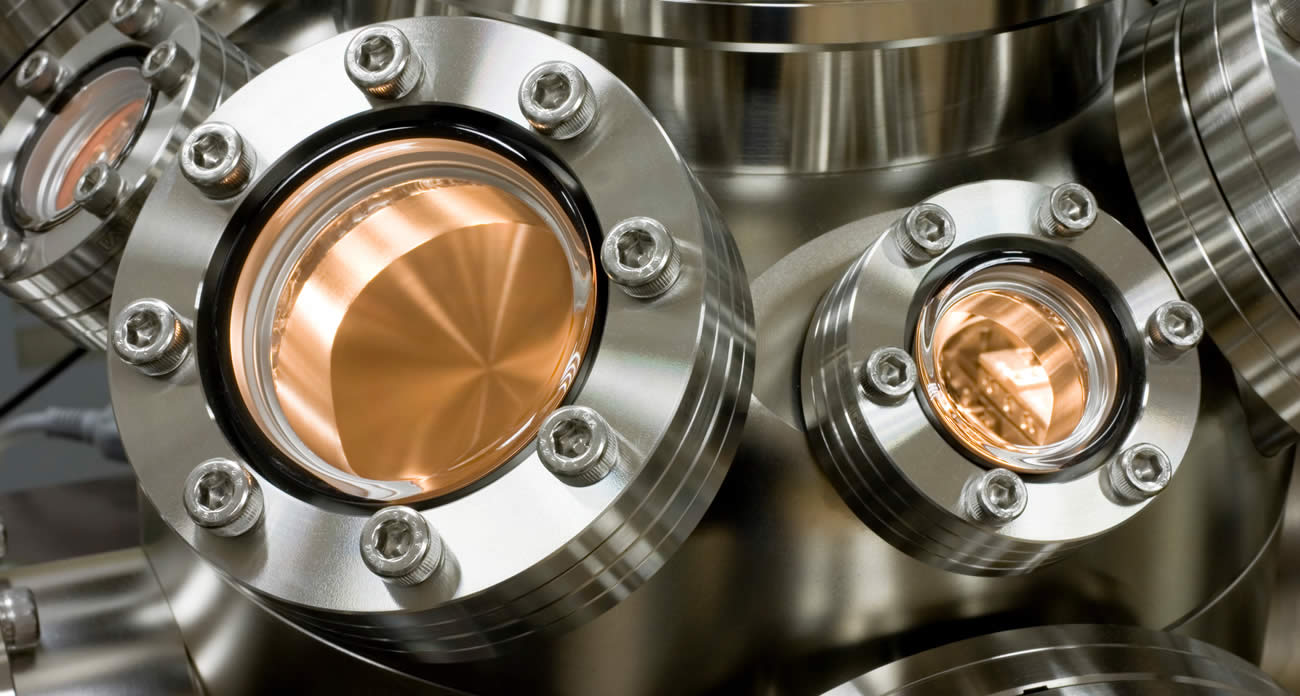

Material selection is also critical. Not all materials are suitable for high vacuum. Plastics, for instance, often outgas a lot. Metals like stainless steel are common because they outgas less and can withstand baking. Special grades of stainless steel are often used. Viton, a type of rubber, is a common material for O-rings, which provide seals in vacuum systems. However, even these materials have limits for the lowest pressures.

Cleanliness is paramount. Dust, fingerprints, and even microscopic particles can release gas into the vacuum. Therefore, we assemble high vacuum systems in clean environments. People wear gloves, and tools are specially cleaned.

Applications of High Vacuum

High vacuum technology is not just for scientists in labs. It plays a role in many products we use daily.

- Semiconductor Manufacturing: This is perhaps the most significant application. Computer chips are incredibly complex. They have billions of tiny transistors. Making these features requires extreme precision and a perfectly clean environment. High vacuum chambers are used for processes like sputtering, where thin films of material are deposited onto silicon wafers, and for etching, where parts of the chip are precisely removed. Without high vacuum, dust particles would ruin the chips, and the deposition processes would not work correctly.

- Thin Film Deposition: Beyond semiconductors, high vacuum helps create thin coatings for many products. For example, anti-reflective coatings on eyeglasses and camera lenses are applied in vacuum chambers. Decorative coatings on jewelry, protective coatings on tools, and even reflective coatings on telescope mirrors all use high vacuum. These processes, like physical vapor deposition (PVD), require a high vacuum to ensure the deposited material sticks well and forms a uniform, pure layer.

- Space Simulation: Before sending satellites or spacecraft into space, engineers test them. They put them in large vacuum chambers that simulate the conditions of space, including the very low pressure. This ensures the spacecraft can withstand the harsh environment.

- Scientific Research: High vacuum is indispensable for fundamental research. Electron microscopes, which let us see incredibly tiny things, need a high vacuum inside. Particle accelerators, which smash atoms to study their fundamental building blocks, operate in ultra-high vacuum to prevent particles from colliding with air molecules. Surface science, which studies the properties of material surfaces, also relies heavily on high vacuum to keep surfaces clean and reactive.

- Freeze Drying: This is a more common application. Freeze drying, used for preserving food, pharmaceuticals, and even historical documents, involves putting a substance in a vacuum chamber. The low pressure allows ice to sublimate directly into water vapor, bypassing the liquid state. This preserves the material’s structure and nutrients better than conventional drying.

Looking Ahead

High vacuum technology continues to evolve. Engineers and scientists always work to achieve lower pressures, develop faster pumps, and design more robust and cleaner vacuum components. The demand for even cleaner and more precise manufacturing processes drives much of this innovation. As our world becomes more technologically advanced, the invisible world of high vacuum will become even more critical. It is a foundational technology that enables many of the breakthroughs we see today and will see tomorrow. It is not just about removing air; it is about creating the right environment for groundbreaking work.